text.skipToContent

text.skipToNavigation

PacDrive3 is part of Modicon

Schneider Electric PacDrive3

PacDrive 3 is based upon proven logic motion technology, which unifies PLC, motion, and robotics control functionality - High Performance Motion Controller

A complete automation solution for motion centric machines

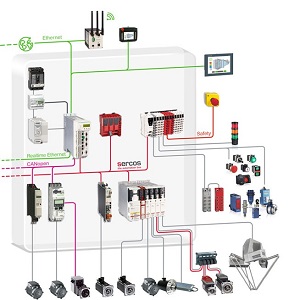

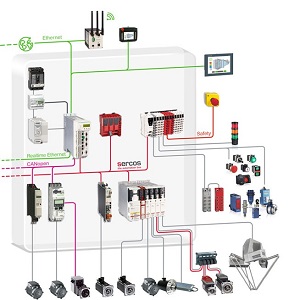

Features PacDrive 3 is based upon proven logic motion technology, which unifies PLC, motion, and robotics control functionality on a single hardware platform. With its centralised system architecture, PacDrive is the ideal solution for controlling a broad range of servo-driven production and packaging machines, as well as material handling equipment and robotics, using fully integrated, IEC 61131-3-compliant program structures. More than 80.000 machines worldwide are controlled by PacDrive to this day.- One integrated, scalable automation platform, scalable controller performance from 0 to 99 servo drives and/or embedded robots

- Single controller solution for motion, PLC logic, and communication; no additional and/or proprietary hardware required for the complete machine (incl. robotics)

- One programming tool / one program for the complete machine, IEC 61131-3 compliant programming design

- Software can be ported between platforms

- Fully integrated Ethernet-based communication using Sercos III for I/O, drive and safe communication

- Open system, supporting other field busses as well as TCP/IP communication

- One of the most flexible drive solutions with single and multiaxis drive solutions, cabinet based and as well integrated servo drives

- SoMachine based tools, supporting the engineering process, including commissioning and diagnostics

- Safety functions (according to IEC 61508: 2010, EN/ISO 13849: 2008)

- Robotic solutions (kinematic packages, including drives, electronics and software) up to IP 65

Benefits

PacDrive 3 is your automation solution for faster time to market and for maximum reliability- Modular programming concept with comprehensive application software libraries for less programming efforts and higher software quality (Libraries for compliance to PackML and Weihenstephan standard, as well FDA and PLCopen compliant library functions)

- Centralised calculation of all axis positions within the controller, allowing the controller to switch on the fly from real to virtual axes. Enables motion testing/simulation without connecting drives/motors

- Standard parameterisation of each axis, configuration of individual drives requires only input of inertia for each load

- Fast device replacement: Electronic type plates for all servo drives/motors, detailed communication with each drive/motor for automatic parameterisation and firmware replication (all data are centrally stored in the controller) and diagnosis

- Fast commissioning with automatic Sercos scan after changing machine configuration/restart: The controller recognises all connected drives/motors and can activate/deactivate them automatically based upon the modules connected to the machine

PacDrive3 is part of Modicon

Schneider Electric Lexium 32i

Read further

The Lexium 32 and motors are part of EcoStruxure Machine. The NEXT generation of EcoStruxure Machine™ from Schneider Electric is an intuitive solution for machine automation with all the features and functions you need to build machines that will improve your bottom line. From design and development, to commissioning and maintenance, EcoStruxure Machine is a complete machine building solution with benefits all through the machine life cycle.

Schneider Electric Lexium 32i

Read further

With servo motor and servo drive integrated in one housing, the Lexium32i is designed for application areas requiring high precision and advanced motor control.

Schneider Electric XIOT

Read further

The Internet of Things IoT is the extension of the Internet to connected devices. Telemecanique Sensors offers a wireless solution to collect data from remote equipment and use this data, via the Internet, on a PC or mobile device. The XIOT Cloud connected switch from Telemecanique Sensors is based on low power wide area network technology, operated by Sigfox. The Sigfox network covers 32 countries and is already very extensive in Europe. It is also being rapidly deployed in the US and Asia-Pacific. It uses antennas with a range of around 50 km. The map on the Sigfox website shows exactly which areas are covered by the Network.

Schneider Electric TeSys Island

Schneider Electric TeSys Island

TeSys™ island is a digital load management solution that makes machines smarter and more reliable. It is a fully digitized, object-oriented load management system and an Industry 4.0 compliant data provider. It reduces machines’ time to market enabling OEMs to move forward in their Industry 4.0 journey. TeSys island gives users easy & remote access to predictive & preventive application data, leading to early diagnostics & maintenance.